1990 Pontiac Firebird Repair Manual

This is the Official Service Manual of the dealerships, written by the manufacturer specifically for the vehicle(s) listed. This ensures you get the job done right the first time. It is very detailed with good diagrams, photos and exploded views. A must for anyone who insists on Genuine OEM quality parts. 11' x 8.5' x 2.2'. Available Conditions.

Very good condition - Covers show little wear. All pages are in place and straight. Page surfaces are clean. Good condition - Covers show some wear. All pages are in place and straight. Page surfaces are mostly clean.

Good usable condition - Covers show wear and soiling. All pages are in place and straight.

Page edges may be lightly soiled. Page surfaces are mostly clean. Product Reviews.

This is the Highly Detailed factory service repair manual for the1990 PONTIAC FIREBIRD, this Service Manual has detailed illustrations as well as step by step instructions,It is 100 percents complete and intact. They are specifically written for the do-it-yourself-er as well as the experienced mechanic.1990 PONTIAC FIREBIRD Service Repair Workshop Manual provides step-by-step instructions based on the complete dis-assembly of the machine. John deere 310e manuals. It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. Complete download comes in pdf format which can work under all PC based windows operating system and Mac also, All pages are printable. Using this repair manual is an inexpensive way to keep your vehicle working properly. 1990 PONTIAC FIREBIRD Service Repair Manual.

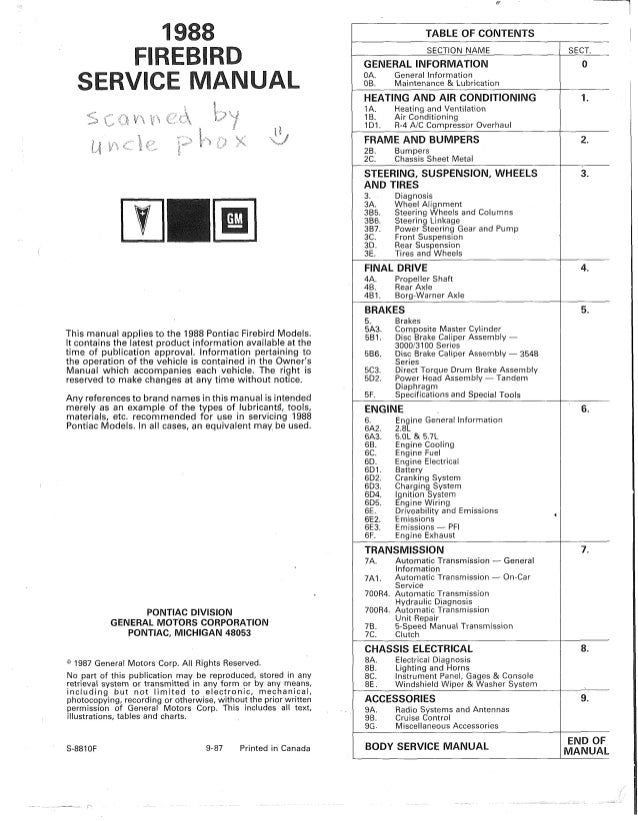

1. 1988 SER This manual applies to the 1988 Pontiac Firebird Models. It contains the latest product information available at the time of publication approval. Lnformation pertaining to the operation of the vehicle is contained in the Owner's Manual which accompanies each vehicle. The right is reserved to make changes at any time without notice. Any references to brand names in this manual is intended merely as an example of the types of lubricant% tools, materials, etc, recommended for use in servicing 1988 Pontiac Models. In all cases, an equivalent may be used.

PONTIAC DIVISION GENERAL MOTORS CORPORATION PONTIAC, MICHIGAN General Motors Corp. All Rights Reserved. No part of this publication may be reproduced, stored in any retrieval system or transmitted in any form or by any means, including b u t n o t l i m i t e d t o electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of General Motors Corp. This includes all text, illustrations, tables and charts. S-881OF 9-87 Printed in Canada TABLE OF CONTENTS SECTION NAME GENERAL INFORMATION OA. General lnformation OB.

Maintenance & Lubrication 1 SECT. HEATING AND AIR CONDITIONING 1A.

Heating and Ventilation 1B. Air Conditioning 1D1. R-4 AIC ComressorOverhaul FRAME AND BUMPERS 2B.

Chassis Sheet Metal STEERING, SUSPENSION, WHEELS AND TIRES 3. Diagnosis 3A.

Wheel Alignment 3B5. Steering Wheels and Columns 3B6. Steering Linkage 3B7. Power Steering Gear and Pump 3C.

Front Suspension 3D. Rear Suspension 3E. Tires and Wheels FINAL DRIVE 4A.

Propeller Shaft 4B. Rear Axle 4B1. Bora-Warner Axle BRAKES 5. Comoosite Master Cvlinder 5B1.

Disc r rake Caliper s s e m b l y- 300013100 Series 5B6. Disc Brake Caliper Assembly -3548 Series 5C3. Direct Torque Drum Brake Assembly 5D2. Power Head Assembly -Tandem Diaohraam 5F. ecificationsand Special Tools ENGINE 6. Engine General lnformation 6A2. 5.OL & 5.7L 6B.

1995 Pontiac Firebird

Engine Cooling 6C. E n i n eFuel 6D. n g i n eElectrical 6D1. Cranking System 6D3. Charging System 6D4. Ignition System 6D5.

Engine Wiring 6E. Driveabilitv and Emissions 6E2.

missions' 6E3. Emissions - PFI 6F. Engine Exhaust TRANSMISSION 7A. Automatic Transmission - General lnformation 7A1.

Automatic Transmission - On-Car Service 700R4. Automatic Transmission Hydraulic Diagnosis 700R4. Automatic Transmission Unit Repair 76. 5-Speed Manual Transmission 7C. Clutch CHASSIS ELECTRICAL 8A. Electrical Diagnosis 8B. Lighting and Horns 8C.

Instrument Panel, Gages & Console 8E. Windshield Wiper &Washer System ACCESSORIES 9A. Radio Systems and Antennas 9B. Cruise Control 9G. Miscellaneous Accessories I BODY SERVICE MANUAL END OF MANUAL. CAUTION To reduce the chance of personal injury and/or property damage, the following instructions must be carefully observed: Proper service and repair are important to the safety of the service technician and the safe, reliable operation of all motor vehicles. If part replacement is necessary, the part must be replaced with one of the same part number or with an equivalent part.

Do not use a replacement part of lesser quality. The service procedures recommended and described inthis service manual are effective methods of performing service and repair.

Some of these procedures require the use of tools specially design- ed for the purpose. Accordingly, anyone who intends t o use a replacement part, ser- vice procedure or tool, which is not recommended by the vehicle manufacturer, must first determine that neither his safety nor the safe operation of the vehicle will be jeopardized by the replace- ment part, service procedure or tool selected. It is important to note that this manual contains various 'Cautions' and 'Notices' that must be carefully observed in order to reducethe risk of personal injury during service or repair, or the possibility that improper service or repair may damage the vehicle or render it unsafe.

It is also important to understand that these 'Cautions' and 'Notices' are not exhaustive, because it is impossible to warn of all the possible hazardous consequences that might result from fail- ure t o follow these instructions. GENERAL INFORMATION OA-1 SECTION (DA GENERAL NFORMAT CONTENTS.General Description OA- 1 Prevailing Torque Fasteners. OA-2.Body Number Plate OA- 1 Recommendations For Fastener Reuse.OA-2.Vehicle Identification Number OA- 1 Vehicle Lifting Procedures.OA-2.Metric Fasteners OA- 1 Precautions Against Tipping. OA-7.Fastener Strength Identification OA-2 Automotive Abbreviations. 0.4- 1 1 GENERAL DESCRIPTION Only general information appears in this section. Left of the windshield, see Figure 2.

Refer to Figure 3 Detailed specifications on major units are given at the for detailed 'VIN' code information. For Engine V.I. End of each respective section of this manual.

Location, refer to Figure 4. BODY NUMBER PLATE METRIC FASTENERS The Body Number Plate (Fig. 1) is attached to Pontiac models are primarily dimensioned in the the front tie bar behind either the right or left headlamp metric system, Most fasteners are metric and are very in the engine On The close in dimension to well-known customary fasteners Number Plate identifies numerous items as outlined in in the inch system.

It is most important that Figure 1. Relacement fasteners be of the correct nominal VEHICLE IDENTIFICATION NUMBER d&meter, thread pitch and strength. Original equipment metric fasteners (except The Vehicle Identification Number (VIN) Plate 'beauty' bolts, such as exposed bumper bolts, and is located on top of the instrument panel at the lower cross recess head screws) are identified by a number 1 -BODY STYLE 2 ASSEMBLY P U N T 3 - UNIT NUMBER 4 -PAINT TYPE 5 -ROOF OPTION 6 - SEAT OPTION 7 -TRIM COMBINATION 8 -UPPER BODY 9 -UPPER COLOR 10 -LOWER BODY 11 -REMAINING LINES -AVAILABLE FOR -PLANT USE 12 -LOWER COLOR 13 -MODEL YEAR 14 -TIME BUILD CODE 15 -DIVISION 16 -BODY TvPE 6200224A Fig. 1 Body Number Plate. OA-2 GENERAL INFORMATION VIN NUMBER PLATE LOCATION Fig. 2 Vehicle Identification Number Plate Location marking indicating the strength of the material in the fastener as outlined below.

Metric cross recess screws are identified by a Posidriv or Type 1A cross recess as shown in Figure 8. Either a Phillips head or Type 1A cross recess screwdriver can be used in Posidriv recess screw heads, but Type 1A cross recess screwdrivers will perform better. NOTICE:Most metric fasteners have a blue color coating. However, this should not be used as a positive way of identifying as some metric fasteners are not color coated.

General Motors Engineering Standards, along with other North American Industries, have adopted a portion of the standard metric fastener sizes defined by IS0 (International Standards Organization). This was done to reduce the number of fastener sizes used and yet retain the best strength qualities in each thread size. For example, the customary 1/4-20 and 1/4-28 screws are replaced by the metric M6.0 X 1 screw which has nearly the same diameter and 25.4 threads per inch. The thread pitch is in between the customary coarse and fine thread pitches. Metric and customary thread notation differ slightly. The difference is shown in Figure 9.

FASTENER STRENGTH ODENTIFIGATION Most commonly used metric fastener strength property classes are 9.8 and 10.9 with the class identification embossed on the head of each bolt. Customary (inch) strength classes range from grade 2 to 8 with radial line identification embossed on each bolt head (i.e., grade 7 bolt will exhibit 5 embossed radial lines on the bolt head). Some metric nuts will be marked with single digit strength identification numbers on the nut face. Figure 12shows the different strength markings. When replacing metric fasteners,be careful to use bolts and nuts of the same strength or greater than the original fasteners (the same number marking or higher).It is also important to select replacement fasteners of the correct size. Correct replacement bolts and nuts are available through the parts division. Many metric fasteners available in the after-market parts channels were designed to metric standards of countries other than the United States.

These fasteners may be of a lower strength, differentthread pitch and may not have the numbered head marking system. The metric fasteners used on GM products are designed to new, international standards that may not be used by some nondomestic bolt and nut suppliers. In general, except for special applications, the common sizes and pitches are: M 6.0 X 1 M 8 x 1.25 M 10 X 1.5 M 12 X 1.75 M 1 4 x 2 I PREVAILINGTORQUE FASTENERS A prevailing torque nut is designed to develop an interference between the nut and bolt threads. This is most often accomplished by distortion of the top of an all-metal nut or by using a nylon patch on the threads in the middle of the hex flat. A nylon insert may also be used as a method of interference between nut and bolt threads (Fig. A prevailing torque bolt is designed to develop an interference between bolt and nut threads, or the threads of a tapped hole.

This is accomplished by distorting some of the threads or by using a nylon patch or adhesive (Fig. RECOMMENDATIONS FOR FASTENER REUSE: I Clean, unrusted prevailing torque nuts and bolts may be reused as follows: a. Clean dirt and other foreign material off nut or bolt. Inspect nut or bolt to insure there are no cracks, elongation, or other signs of abuse or overtightening. (If there is any doubt, replace with a new prevailing torque fastener of equal or greater strength.) c. Lightly coat bolt & nut with engine oil.

Assemble parts and hand start nut or bolt. Observe that before fastener seats, it develops torque per the chart in Figure 10. (If there is any doubt, replace with a new prevailing torque fastener of equal or greater strength.) e. Tighten fastener to torque specified in appropriate section of this manual. Bolts and nuts which are rusty or damaged should be replaced with new parts of equal or greater strength.

VEHICLE LIF'TING PROCEDURES NOTICE: When jacking or lifting vehicle from frame side rails, be certain lift pads do not contact catalytic converter as damage to converter will result. Many dealer servicefacilities and service stations are equipped with a type of automotive hoist which must bear upon some part of the frame in order to lift the vehicle. Figures 14 and 15 indicate the recommended areas for hoist contact for Pontiac Sunbird models. If any other hoist methods are used, special care must be used not to damage the fuel tank, filler neck, I exhaust system or underbody.

I. GENERAL INFORMATION OA-3 PLANT CODE GM PLANT CODES LV.1.N.

POSITION $ 1 1 ) Lakrwood L a n s l n q B Norwood P o n t l a c T a r r y t o w n W1:low Run S t. T h e r e s e L o r d s t o w n 6 0 0 0 S I E 6 0 0 0 STE T r a n s Am G r a n d P r l x G r a n d P r l x LE G. Brougham B o n n e v l i l e B o n n e v l l le LE ( V. POSITION $ 8 ) S u n b l r d GT G r a n d Am G r a n d Am LE G r n dAm SE CARBURETION I MPFI T u r b o Sed,in 7 D,i,r P l a l n Lia.k l I l. t ' l l i. c k Seci.in 4 Utnir 6 $lndi,w Nott'IL.ck c' t i rN o t c h b d c k S p r c l d l Coupe 2 Door C o n v e r t b l r Scd.ln 4 Door b W n d o wP l a l l i Back Scd.jn 4 Uui,r 4 Wl,idir,r N u t c h b d c k Manual B e l t s Manudi B e l t s W l t h B u l l t - I n S d f r t y blaiiual B e l t s V l t l i B u l l t - I n S a f e t y ( D r l v r r O n l y ) Fig. 3 Vehicle Identification Number Data.

OA-4 GENERAL INFORMATION Refer to Fig. 5-Speed (77mm) metal tag attached to extension ENGINE V.I.N. VEHICLE COMPONENT IDEN'IIFICA'T0N NUMBER LOCATION ENGINE CODES: 'EM, 'F', '8' OPTIONAL V.I.N.

LOCATION ENGINE V.I.N. LOCATION Fig.OA-5- EngineV.I.N. Location. GENERALINFORMATION OA-5 -THM 700-R4 TRANSMISSION I.D. LOCATION 1-1 IOU DAY OF THE YEAR1 ISHIFT BUILT 1 1A & B = FIRST SHIFT 1C 5 H - SECOND SHIFT T H M 700-R4 TRANSMISSION IDENTIFICATION NUMBER V I N LOCATION I OPTIONAL VIN LOCATION -I I Fig.OA-6 -TransmissionVIN Location LUBRICATION POINTS CHASSIS - SEE MAINTENANCE SCHEDULE ENGINE OIL AND FILTER COOLING SYSTEM WHEEL BEARINGS AUTO TRANSMISSION FLUID LOWER CONTROL ARM BALL JOINTS II ENGINE COMPARTMENT STEERING LINKAGE Fig. OA-7 Typical Lubrication Points. OA-6 GENERAL INFORMATION USING FRAME CONTACT HOIST USING FRAME CONTACT HOIST REARWARD OF FRONT TIRE ' FORWARD OF REAR TIRE USING SUSPENSION CONTACT HOIST LIFTING ON REAR AXLE USING SUSPENSION CONTACT HOIST UNDER FRONT LOWER CONTROL ARM 520016-0A Fig.

8 Vehicle Lifting Points 'F' Model. GENERAL INFORMATION OA-7 APPROXIMATE CAPACITIES Fuel Injected Models. CRANKCASE 5.OL V8 Oil Change.Approximate capacity with or without oil filter change. Crankcase capacities shown are approximate refill capacities. After refill, recheck oil as outlined in the Owner's Manual. COOLING SYSTEM 2.8L V6 Without A/C 5.OL V8 Without A/C Fig.

OA-9 Fluid Capacties. 08-8 GENERAL INFORMATION USE OF METRIC AND CUSTOMARY NUTS, BOLTS AND SCRERS Some vehclespresent specalservlce requrementsto the technrcaldue to the use of both metnc and cus- tomary (Inch)type nuts, bolt5 and screws. Many are metnc and some are very close in dmensonto custom- ary nuts. Bolts and screws in the Inch system Msmatchedor Incorect nut5, bolt5 and screus can result rn damage, malfunctonor possblepersonal Injury Nuts. Bolts and screws removed from the vehcle5hould be saved for re-use uhenever poscrble.

If they are not re-usable. Care should be taken to select a replacement that matches the ongnal. General Motors EngneenngStandards have ddopted a portion of the standard metnc fastener slzes defined by SI (Systeme Internatronal) T h swas done to reduce the number of srzes used and yet retarn the best strength characterstcsIn each thtead size. The customary 114-20and 1/4-28screws are replaced by the metrlc M6.3 x I screw whchhas nearly the same dameterand 25.4 threads per inch.

The thread ptch IS In between the customary coarse and fine thread prtches. Metnc and customary thread notatlon dfferslghtly.The dfferenceIS llustratedbelou. CUSTOMARY METRIC Thread Major Thread Major Dameter Dameter ninches rn Mllmeters Number of Dstance Threads Between Threads in Millmeters Care should be taken when servlclng the vehcleto guard agalnst cross threadngor Improper retention due to interchanged metnc and inch nuts and bolts. When obtarnngmetnc or customary nuts, bolts, and screws locally for servrcing the vehicle.

Care must be exercsedin selecting parts that are equrvalent to the ongnalparts In dimensions. And ptchof Fig.OA-10 -Metric Information, Chart A. GENERAL INFORMATION OA-9 REUSE OF PREVAILING 'TRQUE NUT AND BOLT WASHER NYLON STRIP OR PATC I A. CLEAN, llNRUSTFD PREVAILING TORQllF BOLTS AND NL'TS MAY Bk. REUSED AS FOLL.0WS II.

CLEAN DIRT AND OTHER FORFICN MATERIAL OFF NUT AND BOLT. 2, INSPECT BOLT AND NUT TO ASSURE THERE ARE NO CRACKS. ELONGATION OR OTHER SIGNS OF ABUSE OR OVERTIGIiTENING.

1991 Pontiac Firebird

LIGHTLY LUBRICATE THREADS. (IF ANY DOUBT, REPLACE WITH NEW PREVAILING TOROLE FASTENER OF EQUAL OR GREATER STRENGTH.) 3.

ASSFMBLE PARTS AND START BOLT OR NLIT. OBSERVE THAT BEFORE FASTENER SkATS. IT DEVk.LOPS PREVAILING TORQUE PER CHART BELOW. (IF ANY DOUBT, INSTALL NliW PRFVAILIN(; TORQL'F FASTENER OF EQUAL OR GREATER STRENGTH). TIGHTEN TO TORQUE SPECIFIED IN SERVl('k MANl'AL,. OA-10 GENERAL INFORMATION METRIC BOLT AND NUT IDENTIFICATION Common metric fastener strength property classss are 9.8 and 10.9 with the clers idsntifica$ion embossed on the haad of each bolt.

Customary (inch) strength clases range from grade 2 to 8 wi(h line ihntificaion embosssd on each bolt head. Markings correspond to two lines lsss than the actual grade (i.e. Grade 7 bolt will exhibit 5 embossd lines on the bolt head).

Some metric nuts will be markd with single digit strength identification numbers on the nut face. The following figure illustr&es the different strength markings. Customary (nch)bolts - ldentfcatonmarks correspond to bolt strength - lncreasngnumbers represent lncreaslng strength. MetrcBolts - ldentfcatonclass numbers correspond to bolt strength - lncreasngnumbers represent lncreaslng strength. MANUFACTURERS NUT STRENGTH IDENTIFICATION IDENTIFlCATlON POSlDRlV Fig.OA-12 - Metric Information,Chart C.

SI METRIC-CUSTOMARYCONVERSIONTABLE to get equivalent by nurnber of: Multiply to get equivalent by numberol:Multiply LENGTH ACCELERATION Inch Foot Yard Mile millimeters (mm) meters (m) meters kilometers (km) TORQUE AREA newton-meters (N-m) newton-meters millimeters2 (mm2) centimeters2 (cm2) meters' (m2) meters2 POWER Horsepower VOLUME PRESSUREOR STRESS 3.377 6.895 mm3 cm3 liters (I) liters liters meters3 (ma) Inchesof mercury Poundslsq. Kilopascals (kPa) kilopascals Quart Gallon Yard3 ENERGY OR WORK BTU Foot-pound Kilowatt-hour joules (J) joules joules (J = one W's)MASS Pound Ton Ton kilograms (kg) kilograms(kg) tonne (t) Foot candle FORCE FUEL PERFORMANCE Kilogram Ounce Pound newtons (N) newtons newtons Mileslgal Gallmile kilometerslliter (km/l) literslkilometer (Ilkm) TEMPERATURE VELOCITY 1.609Degree Fahrenheit degree Celsius (C) Mileslhour. OA-12 GENERAL INFORMATION DECIMAL AND METRIC EQUIVALENTS Fractions Decimal Metric Fractions Decimal In.

Fig.OA-14.Metric Information, Chart E.GENERALINFORMATION OA-13 LIST OF AUTOMOTIVE ABBREVIATIONS WHICH MAY BE USED IN THIS MANUAL A-6 - Axial 6 Cyl. A C Compressor AIC - Air Conditioning ACC - Auto'matic Climate Control EMF - Electromotive Force PAIR - Pulse Air Injection Reaction System EMR - Electronic Module Retard P B - Power Brakes EOS - Exhaust Oxygen Sensor PCV - Positive Crankcase Ventilation ESC - Electronic Spark Control PECV - Power Enrichment Control Valve APT - Adjustable Part Throttle AT - Automatic Transmission ATC - Automatic Temperature Control ATDC - After Top Dead Center FMVSS - Federal Motor Vehicle Safety BAR0 - Barometric Absolute Pressure Sensor Ft. Foot Pounds (Torque) Bat. + - Positive Terminal FWD - Front Wheel Drive - Four Wheel Drive BHP - Brake Horsepower 4 x 4 - Four Wheel Drive BP - Back Pressure BTDC - Before Top Dead Center HD - Heavy Duty HE1 - High Energy Ignition Cat.

Catalytic Converter CC - Catalytic Converter - Cubic Centimeter - Converter Clutch CCC - Computer Command Control HVM - Heater-Vent-Module IAC - ldle Air Control CCOT - Cycling Clutch (Orifice) Tube IC - Integrated Circuit CCP - Controlled Canister Purge ID - Identification C.E. Check Engine - Inside Diameter CEAB - Cold Engine Airbleed ILC - Idle Load Compensator CEMF - Counter Electromotive Force I/P- Instrument Panel CID - Cubic Inch Displacement ISC - Idle Speed Control CLOOp - Closed Loop CLCC - Closed Loop Carburetor Control km - Kilometers CP - Canister Purge kmiL - Kilometers Liter (mpg) Cu. Cubic Inch kPa - Kilopascals CV - Constant Velocity Cyl.

Cylinder(s) L-4 - Four Cylinder In-Line (Engine) DBB - Dual Bed Bead L-6 - Six Cylinder In-Line (Engine) DBM - Dual Bed Monolith LF - Left Front DEFl - Digital Electronic Fuel Injection LR - Left Rear DFI - Digital Fuel Injection Diff. Differential Man. Manifold Vacuum Distr.

Distributor MAP - Manifold Absolute Pressure EAC - Electric Air Control Valve EAS - Electric Air Switching Valve MPG - Miles Per Gallon ECC - Electronic Comfort Control MPH - Miles Per Hour ECM - Electronic Control Module MT - Manual Transmission N. M - Newton Metres (Torque) Emission Control Fig.014-15- CommonAbbreviations. 0.4-14 GENERAL INFORMATION SERVICE P A R E SlDENTlFlGATlON LABEL The Service Parts Identification Label providesidentifi- fixed to the inside of each passenger car vehicle at the cation of vehicle equipment to assist in servicing and assembly plant. Determining replacement parts, Included on this label will be regular production options (RPO's) as well as For additional information on the Service Parts Identifi- standard and mandatory options. The label will be af- cation Label, see a GM Parts Catalog. VEHICLE -f IDENTIFICATION NUMBER lGlAZ3799ER157148 1JD69 A R L A02 A65 BGY B9A B9K C60 D l 0 D35 E5Z E6E E9Z FLT GU1 JM7.